Wafer production

Increase yield while ensuring the highest quality and process reliability, even in ongoing wafer production.

Our inline optical inspection systems reliably detect defects on the surface, at the edge and inside the bulk wafer material to significantly increase your production capacity. Save costs by removing defective material before it reaches the next stage of the production process.

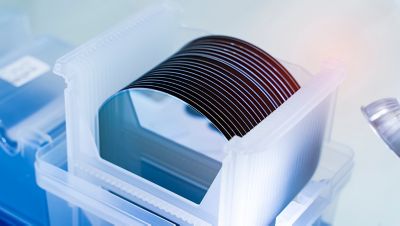

Post-Grinding / Pre-Polishing Inspection

CMP eliminates micro peaks and valleys.

However, microcracks in the bulk wafer material or at the wafer edge can lead to wafer breakage during polishing or other downstream processes, resulting in high costs. Defective wafers must be rejected in time to avoid expensive cleaning and extended machine downtime.

Benefits

- Increased uptime: Microcrack detection minimizes wafer breakage during the polishing process

- Flexibility: Seamless integration into existing process lines

- Efficiency: Simultaneous scanning of bulk and surface at line speeds of up to 180 wafers/hour

- Features

- Typical defects

- Technical data

- Defect detection down to <5 ?m crack width

- Wafer mapping / 2D coordination map

- Inspection of the wafer edge from three perspectives

- Scan speed: Up to 130°/sec

- Optional notch inspection

- Chippings

- Micro-cracks

- Etch residuals

- Scratches on the front and rear side

- Crystal defects (twin-lamella)

- High-resolution line scan cameras with LED line illumination using different wavelengths

- Integrated adjustment of thresholds and crack characteristics for sensitive optimization of the detection result

- Typ. resolution: 20 μm, optional down to 1,5 μm

- Optical Setup for edge inspection: 2 × 45° prisms & direct side view for 3-sided image acquired

- Semi standard interface

Download additional information

CrackScan brochure en

- Filename

- brochure-crackscan-semiconductor-en.pdf

- Size

- 311 KB

- Format

EdgeScan brochure en

- Filename

- brochure-edgescan-semiconductor-en.pdf

- Size

- 464 KB

- Format

CrackScan brochure cn

- Filename

- brochure-crackscan-semiconductor-cn.pdf

- Size

- 488 KB

- Format

EdgeScan brochure cn

- Filename

- brochure-edgescan-semiconductor-cn.pdf

- Size

- 523 KB

- Format

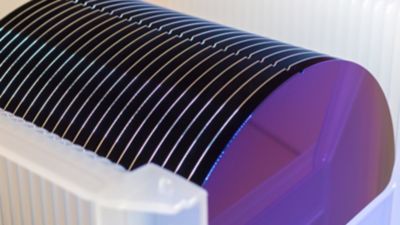

Final Quality / End-of-line Inspection

Improve production yields with 100% in-line inspection, even at high inspection speeds. Using patented MultiView technology, our systems reliably identify and classify macro defects, handling scratches or etch residues. This allows defective wafers to be removed from the process at an early stage.

Benefits

- Continuous and complete process control

- Defect detection in a wide range of coating and lamination techniques

- Defects detection on both sides of the web

- Checking of register accuracy

- Features

- Typical defects

- Technical data

- Defect detection on wafer surfaces and wafer edges

- Rear side inspection (non-functional side)

- Front side inspection for GaAs (relaxed requirements)

- Automatic defect classification

- Optional notch inspection

- Scratches on the front and rear side

- Etch pits (?round“ polished) on the front side

- Etch defects esp. on the rear side

- Etch residuals

- Edge chippings

- High-resolution line scan cameras

- Highest throughput 50 -100 wph (appl. dep.)

- MultiView technology with adapted wavelength and resolution

- Pixel resolution: typ. 3 μm/px

- Semi standard interface

Download additional information

EdgeScan brochure en

- Filename

- brochure-edgescan-semiconductor-en.pdf

- Size

- 464 KB

- Format

WafQScan brochure en

- Filename

- brochure-wafqscan-semiconductor-en.pdf

- Size

- 233 KB

- Format

EdgeScan brochure cn

- Filename

- brochure-edgescan-semiconductor-cn.pdf

- Size

- 523 KB

- Format

WafQScan brochure cn

- Filename

- brochure-wafqscan-semiconductor-cn.pdf

- Size

- 339 KB

- Format

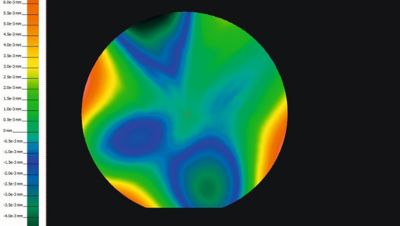

SpecGAGE3D ensures wafer planarity

Wafer planarity is essential for perfect assembly. SpecGAGE3D is a compact solution for efficient quality inspection of reflective surfaces. Using deflectometry, height deviations, and defects are reliably detected in a single measurement.

The measurement data is compared to the CAD data, and differences are evaluated within seconds. The system quickly and efficiently determines whether the manufactured wafers are within the required dimensional tolerances. This enables users to minimize production waste while optimizing processes and machine settings.

Integrated into fully automated production lines, SpecGAGE3D permanently improves the process and reduces production costs.

Benefits

- Detects defects on the front and back side of the web

- Reliable checking of register accuracy

- Continuous and seamless process control

- Features

- Typical defects

- Technical data

- Precise height measurement on reflective surfaces for wafer shape inspection

- High detection rate with extremely low slope variations

- Evaluation according to shape and surface defects

- Shape deviations

- Waviness

- Scratches, inclusions, dots

- Measuring principle: Phase measuring deflectometry

- Measuring fields: 300x200 - 600×400 mm?

- Lateral resolution: ~ 20-240 ?m

- Accuracy elevation map: +/- 10 μm on 10×10 cm?

Download additional information

SpecGAGE3D [EN]

- Filename

- mvs-sfa-fl-specgage3d-en-2025-01.pdf

- Size

- 496 KB

- Format

?? ?? - ??? ?? ?? ???

? ?? ?? ?? ???? ?? ?? ?? ??? ??? ??? ??? ????? ?? ???? ????? ??? ? ????. ?? ?? ???? ?? ?? ???? ????, ?? ?? ???? ????? ??????, ?? ??? ?? ??? ??? ? ????.

?? ???

????? ?? ?? ??? ?? ???? ?? ?? ???? ???? ???? ?? ?? ????? ?? ? ????. ?? ?? ?? ?? ??? ?? ??? ??? ???? ?? ??? ?? ? ?? ?? ??? ???? ?? ? ????. ??? ??? ?? ??? ????? ???? ???? ?? ???? ?? ?? ??? ? ????

?? ?? ?? ??

??? ?? ??? ?? ??? ?? ??? ?? ???? ??? ??? ??? ???? ???? ??? ? ????. ? ?? ?? ??? ???? ???? ?? ?? ??? ???? ?? ??? ??? ? ????.

?? ????

??? ???? ???? ??? ???? ???? ???? ??? ??? ??? ? ????. ?? ?? ??? ??? ??? ?? ??? ?? ??? ???? ????? ??? ??? ? ????. ??? ??? ?? ?? ??? ????? ??? ???? ???? ????? ??? ??? ?? ??? ?? ?? ??? ?????.

??

- ??? ??? ? ?? multi-line overview, ?? ?? ?? ??? ? ?? ? ? ?? One view ???

- ??? ?? ??? ?????? ???? ???

- ?? ??? ?????? ?? ??? ?? ??? ??

- ?? ??? ??? ??, ?? ?? ??

- ???? ???? ???? ??, ?? ??? ?? ? ?? ?? ?? ??

??

- ?? ??? ? ?? ??? ?? Overview

- ??? ????? ?? Live ? ???? ??

- ? ?? ??? (????? ????? ?? ?? ??)

- ??? ???? ? ??

- ??? ??? ????, ??? ?? ?? ??

- ?? ?? ??? ?? ?? ? ?? ????? ??? ???? ??

??? ??? ??? ? ?? ??

?? ???? ????? ?? ???? ??? ?? ??? ??? ?? ????? ?? ??? ?? ? ????? ??? ?????. ???? 24?? ???? ????? ???? ??, ???? ? ???? ?? ?? ? ???? ?????.

?? ??? ????? ?? ??? ???, ?? ???? ? ?? ???? ??? ?? ???? ? ? ??? ????? ?? ?? ??? ???? ??? ?????? ISRA ????? ?????.